Factory making Flange Angle Seat Valve - Metal To Metal Seat Ball Valve – GMK Valve

Short Description:

Factory making Flange Angle Seat Valve - Metal To Metal Seat Ball Valve – GMK Valve Detail:

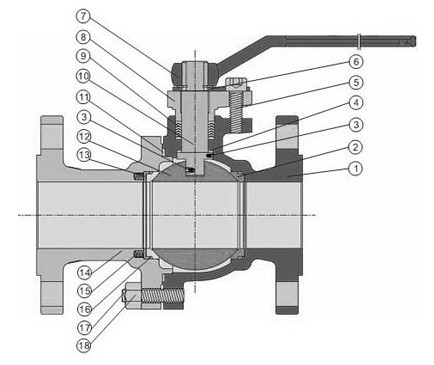

Product name:Metal To Metal Seat Ball Valve

Size:2″-24″

Rating:150LB,300LB,600LB,900LB,1500LB

Material:WCB, LCB,LCC, WC6,WC9, C5,C12,C12A, CF8, CF8M, CF3, CF3M, CN7M,Alloy 20,Duplex,B148 ect

Connection:Flanges,RTJ Flange,Butt Weld,Hub end,Groove

Operate:Hand leverl, Gearbox, Penumatic Actuator, Electric Actuator, Hydraulic Actuator

Feature:

1.Two pieces or Three pieces design

2.Floating ball or Trunnion mounted ball, Anti-blow out stem

3.Full Port Or Reduced Bore

4.Fire safe design and Anti-Static device.

5.ISO 5211 mounting design upon request,suitable for various driving types

6.NACE MR-01-75

7.Maximum temperature: 400

8.The specially-designed compensatory movable valve seat construction made from metal which is of great reliability in its sealing performance.

9.High precision ball& High tightness seat

10.Long life ball&seat

11.The best fire safe and static resistance safety

12.The metal to metal ball valve adopts spring seat structure, which can push upstream seat tightly against the ball surface creating a reliable seal even if extremely low pressure.

13.Valve stuck under high temperature preventedIn case of high temperature working condition, the valve seat and ball would possibly get stuck due to heat expansion, and the valve could not be open. Our metal to metal seated ball valves employ the design of beveling spring loading, which would absorb the heat expansion of parts caused by the beveling spring. Then, it is ensured that the valve would not get stuck and realize easily open and close in case of high temperature condition.

Standard:

1.Design and Manufacture:API6D, ASME B16.34

2.Pressure-temperature rating: ASME B16.34

3.Face to face(end to end):ANSIB16.10

4.End Connection: 2″-24″ ASME B16.5; 26″ -42″ ASME B16.47; B.W end ASME B16.25

5.Test and inspection:API598,API6D

6.Fire safe design:API607,API6FA

Product detail pictures:

Related Product Guide:

Global Forged Automotive Component Market Forecast to 2025 | Pneumatic Actuator Butterfly Valve

Selecting the Optimum Pump Control Valve to Save Substantial Wasted Energy Dollars | Pneumatic Actuator Butterfly Valve

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Factory making Flange Angle Seat Valve - Metal To Metal Seat Ball Valve – GMK Valve, The product will supply to all over the world, such as: Nigeria , Seychelles , Libya , Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.